4 Simple Techniques For Bayside Laser

Wiki Article

Bayside Laser Can Be Fun For Everyone

Table of ContentsEverything about Bayside LaserGetting The Bayside Laser To WorkSome Known Questions About Bayside Laser.The 7-Second Trick For Bayside LaserRumored Buzz on Bayside LaserThe 8-Second Trick For Bayside Laser

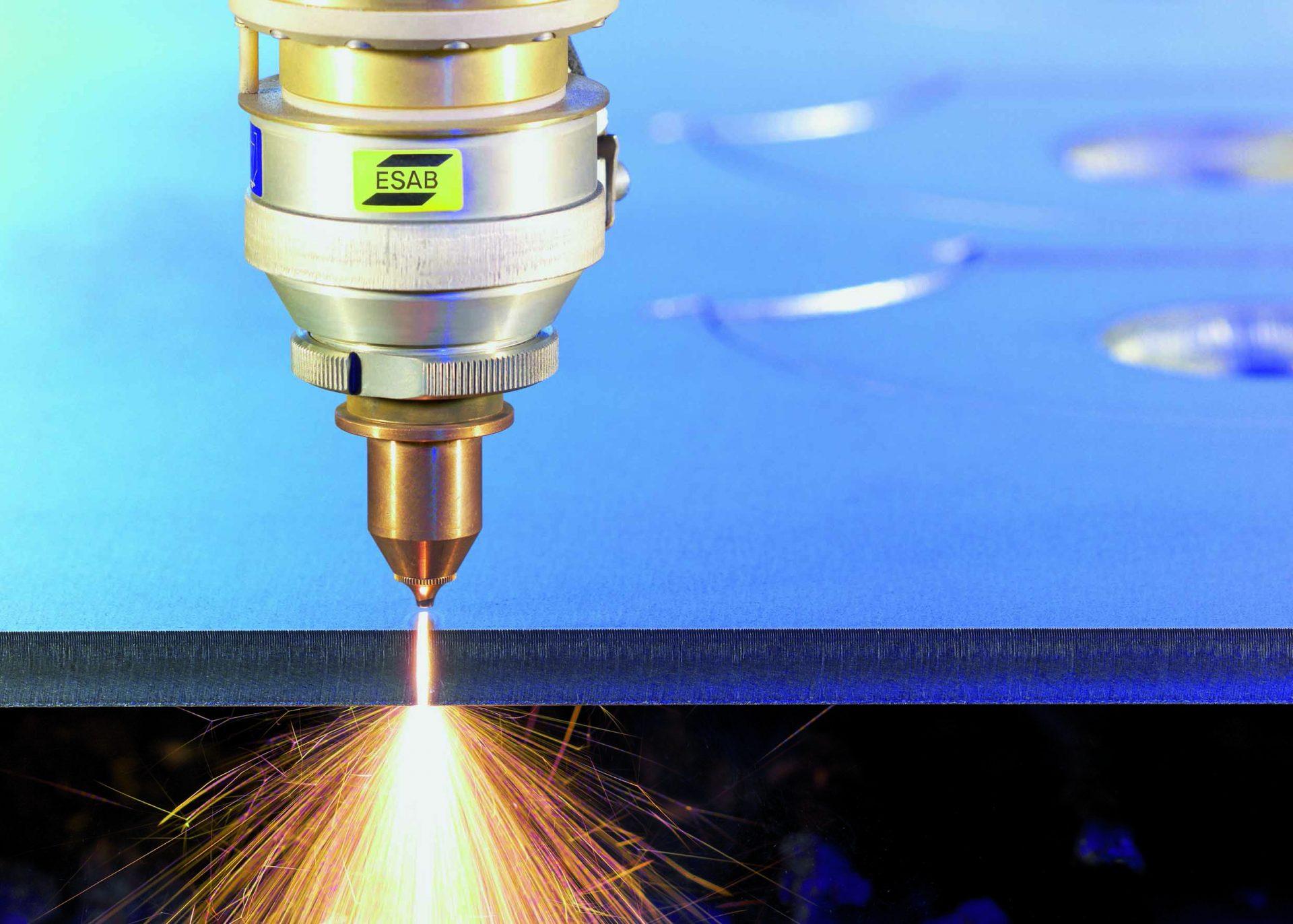

Flying optic equipments should make use of some technique to think about the transforming light beam length from the near area (close to the resonator) cutting to the much area (far away from the resonator) cutting. Typical approaches for regulating this include collimation, flexible optics, or using a constant beam of light size axis.

The power intake as well as performance of any particular laser will certainly differ relying on output power and operating criteria. This will certainly depend on the kind of laser as well as how well the laser is matched to the operate at hand. The amount of laser reducing power required, called warm input, for a particular work depends on the material kind, density, procedure (reactive/inert) made use of, as well as preferred cutting rate.

5 Easy Facts About Bayside Laser Described

Utilizing computerised systems permits for specific and intricate shapes that would certainly have been difficult with typical cutting (laser cutting brisbane). The individual can quickly manage the cut's depth by changing the laser beam of light's power and also focus. Laser cutting is regular in metal, wood, plastics and materials. However it likewise has applications for engraving, etching and also noting.Whether you're searching for a new or updating your processes, laser cutting has wide applications, particularly in manufacturing. That stated, right here are four advantages of laser cutting: Laser reducing is among one of the most sophisticated, specific and exact approaches for cutting products. It can give a level of information and also accuracy that hand tools can never ever reach.

Our Bayside Laser Statements

The capacity for laser cutting appears practically limitless as it uses businesses top quality typical results in a portion of the time. Laser-cutting modern technology is flexible and also compatible with numerous materials, varying from timber and leather to more difficult-to-cut metals. For these harder-to-cut products, laser cutters develop ideal accuracy cuts that are not readily available with conventional cutting devices.Laser-cutting equipments are as uncomplicated as most devices goes. Still, here are four pointers to help get one of the most out of your procedure: With laser cutting, choosing the ideal material for the task is paramount. Depending upon the desired application, various materials may be better than others depending upon variables visit this page such as longevity and security.

The Single Strategy To Use For Bayside Laser

Clearly, laser cutting is a whole lot faster than the standard technique of reducing metal, but is it quicker than other contemporary techniques? Laser cutting beats thermal reducing approaches such as plasma or fire in rate when reducing metal of up to 10mm thick.For those that need to reduce great deals of different forms, laser cutting is certainly one of the most appealing metal reducing option. With this method of reducing metal, you do not require to change devices to alter cuts as the specific same arrangement will execute several reducing tasks as long as the density continues to be the exact same.

Throughout the laser cutting procedure, the beam made use of does not actually require to touch the material that is being cut, causing less danger of damage. This indicates that you will certainly not need to sustain costly fixings or delayed conclusion times as you may with various other methods of cutting steel - laser cutting brisbane.

Bayside Laser Can Be Fun For Anyone

Laser reducing needs much less power than various other methods, making use of typically 10k, W of power compared to 50k, W for other cutting processes. Certainly, the safety and security of your employees is always at the forefront of your mind and laser cutting offers one of the safest ways of cutting metal.That accurate point develops an extremely high intensity that can cut via the product. Contrasted to standard cutting approaches, laser reducing offers numerous benefits.

Unlike lots of producing machines, laser cutters commonly do not require you to switch out various tools for whatever cut you desire. Laser cuttings offer severe accuracy contrasted to other standard cutting techniques.

Indicators on Bayside Laser You Need To Know

Depending on exactly how a laser cutter is established, you're frequently mosting likely to observe perhaps a tiny burr on a part. Normally, it's not essential to remove the burr, however it depends upon the product, its density as well as various other factors. Oh yes, this is among the finest components of making use of a laser cutter; versatility.

An extremely narrow section of material is quickly navigated by the high-powered laser as well as is extremely seldom deformed or distorted. Lasers have the ability to cut stainless steel, aluminum, copper, and brass.

Report this wiki page